CASES & NEWS

Related News

Related Products

Precision and Power: The Role of Stage Machines in Modern Event Design

Views:

Author: Shinestage

Publish Time: 2025-11-14

Origin:

The silent force behind performance perfection

Every memorable performance — from Broadway musicals to Olympic ceremonies — relies on one essential yet often unseen element: stage machinery. Beneath the glittering lights and artistic choreography, complex mechanical systems quietly control movement, precision, and timing.

These machines form the invisible foundation of stagecraft, allowing performers to rise, rotate, or disappear in perfect harmony with music and light. For YONAH Stage Technology (Shinestage), this invisible art of movement represents the ultimate balance between engineering precision and creative imagination. Stage machines are no longer just tools; they are instruments of expression that define how modern stages breathe and move.

Engineering movement with intent

At its core, a stage machine translates creative concepts into mechanical reality. Whether it’s a hydraulic lift elevating a grand piano, or a synchronized platform that transitions scenes within seconds, these systems must perform flawlessly.

Shinestage’s stage machinery integrates electric hoists, lifting platforms, rotation systems, and motion control within a single intelligent framework. The focus lies in modularity and synchronization — machines that communicate with lighting, sound, and visual systems through digital protocols.

This mechanical choreography allows stage designers to orchestrate transformations that feel effortless. In large-scale concerts or theater productions, the precision of every movement defines the rhythm of the show. A one-second delay or imbalance can break immersion. Hence, every Shinestage mechanism undergoes meticulous testing to ensure silence, stability, and repeatable accuracy.

The evolution of stage machinery: from manual labor to automation

The history of stage machinery stretches back centuries — from ropes and pulleys in Renaissance theaters to manually operated trapdoors in early opera houses. However, the modern era of performance demands more than human strength; it demands synchronized intelligence.

Today, stage machines operate through computerized control systems that allow engineers to pre-program every lift, slide, and rotation. This evolution reduces labor, increases precision, and enhances safety.

Shinestage embraces this transformation with smart motion control systems capable of millisecond-level accuracy. Using servo motors, sensors, and programmable logic controllers (PLCs), each device responds instantly to operator input. What once took hours of manual adjustment can now be executed automatically at the touch of a button.

This combination of mechanical robustness and digital intelligence defines the future of stage automation — an arena where creativity is limited only by imagination, not by physics.

Safety: the invisible priority

The beauty of a stage machine lies in its reliability — and reliability begins with safety. Every moving element, whether lifting a ton of lighting equipment or raising a full stage platform, must adhere to strict safety standards.

Shinestage’s machinery follows EN17206, CE, and ISO9001 certifications, ensuring all equipment meets or exceeds international load, speed, and redundancy criteria. Each hoist and lift is designed with dual-safety mechanisms — including limit switches, overload sensors, and emergency stop systems — that protect both the performers and the structure.

Additionally, the use of high-tensile steel cables, precision bearings, and sealed drive units ensures durability even in extreme environments. Whether used in a humid coastal arena or a freezing mountain festival, Shinestage’s systems perform consistently with minimal maintenance.

Integration: uniting art and automation

In modern event design, stage machinery no longer operates in isolation. It interacts seamlessly with lighting consoles, video servers, and sound systems to create immersive, synchronized experiences.

A rotating stage might align perfectly with a video projection; an automated lift could reveal a performer in sync with a laser cue. This level of precision is possible through DMX and Ethernet-based communication protocols, allowing unified control across different devices.

Shinestage develops machinery that integrates directly into these networks, simplifying setup and ensuring smooth coordination between artistic and technical teams. The result is a stage that “thinks” — a responsive, living platform where technology and emotion converge.

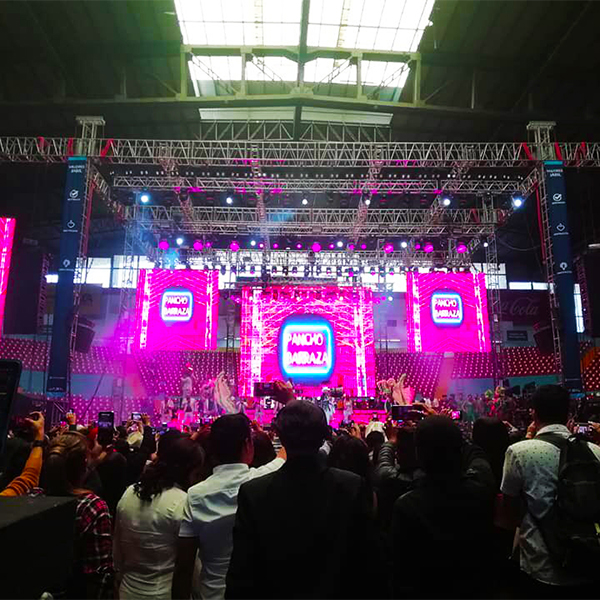

Global applications: from theaters to mega-events

The applications of stage machinery extend far beyond entertainment. In theaters, it supports seamless scene transitions. In concerts, it drives dynamic stage changes and performer lifts. In corporate shows, it elevates product launches into immersive storytelling experiences.

Internationally, Shinestage systems have been applied in cultural centers, national pavilions, and outdoor festivals. Their flexibility makes them ideal for touring productions, where transportability and quick installation are essential.

Moreover, the adoption of compact, foldable machinery components has allowed global event producers to reduce logistics costs while maintaining world-class performance quality. This balance between mobility and mechanical complexity defines Shinestage’s approach to serving international markets.

Sustainability in motion

While stage machinery is inherently mechanical, its future is increasingly green. Shinestage emphasizes energy-efficient motors, recyclable materials, and low-maintenance designs that minimize operational waste. Electric lifting systems replace traditional hydraulics to reduce oil use and environmental risk.

Through optimized motor control and smart standby functions, overall power consumption is reduced without compromising performance speed. This commitment to sustainability not only aligns with global environmental goals but also extends the operational life of each product — reducing total cost of ownership for clients worldwide.

The future: intelligent motion design

Looking ahead, stage machinery is moving toward AI-assisted control and predictive maintenance. Systems will soon be able to self-diagnose wear, adjust performance based on load, and simulate movement before execution.

Shinestage’s R&D team continues to explore innovations in machine learning and motion synchronization, aiming to give designers real-time creative freedom. Imagine programming a lift or rotation through virtual reality and watching it execute perfectly in the physical world — that is where the next generation of stage engineering is heading.

In this vision, the machine becomes not just a servant of art, but a partner in creation.

Conclusion: where precision meets imagination

Stage machinery is the heartbeat of modern performance. It merges precision engineering with artistic expression, transforming static platforms into dynamic worlds. Through innovation, safety, and intelligent design, Shinestage continues to redefine how technology supports creativity.

In every moving platform, lifting hoist, and rotating stage lies a simple truth — motion, when mastered, becomes magic. And that magic is what keeps audiences around the world in awe.