CASES & NEWS

Related News

Related Products

The Global Shift Toward Modular Stage Engineering

Views:

Author: Shinestage

Publish Time: 2025-10-31

Origin:

For decades, the global stage industry was built on craftsmanship—structures assembled piece by piece, welded on site, customized for every unique project. Those stages carried the weight of creativity but also the burden of inefficiency. Time-consuming installation, high labor costs, and inconsistent safety standards defined the traditional workflow. As the world of live entertainment, cultural events, and global touring expanded, the demand for faster, safer, and more flexible systems reshaped the entire engineering landscape.

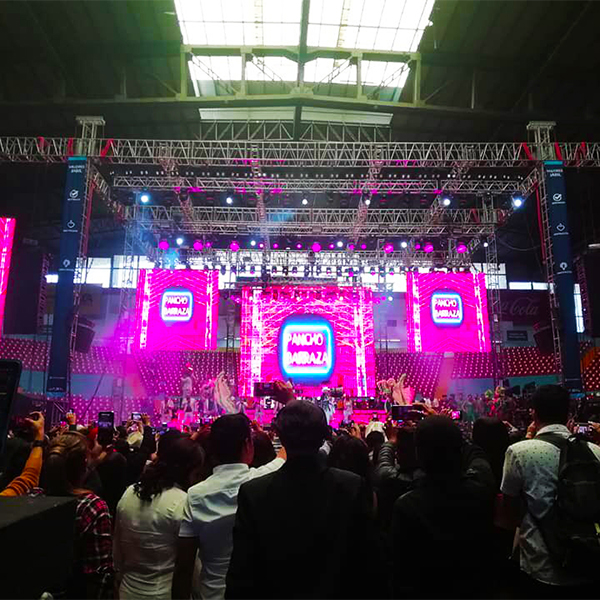

The rise of modular stage engineering represents more than a technical upgrade—it marks a fundamental rethinking of how performances are created, executed, and experienced. The idea that stages could be standardized, reconfigurable, and globally deployable has transformed what used to be a localized craft into a structured, repeatable, and scalable system. What once took several days to build can now be assembled in hours, while maintaining precision and consistency that traditional methods could rarely achieve.

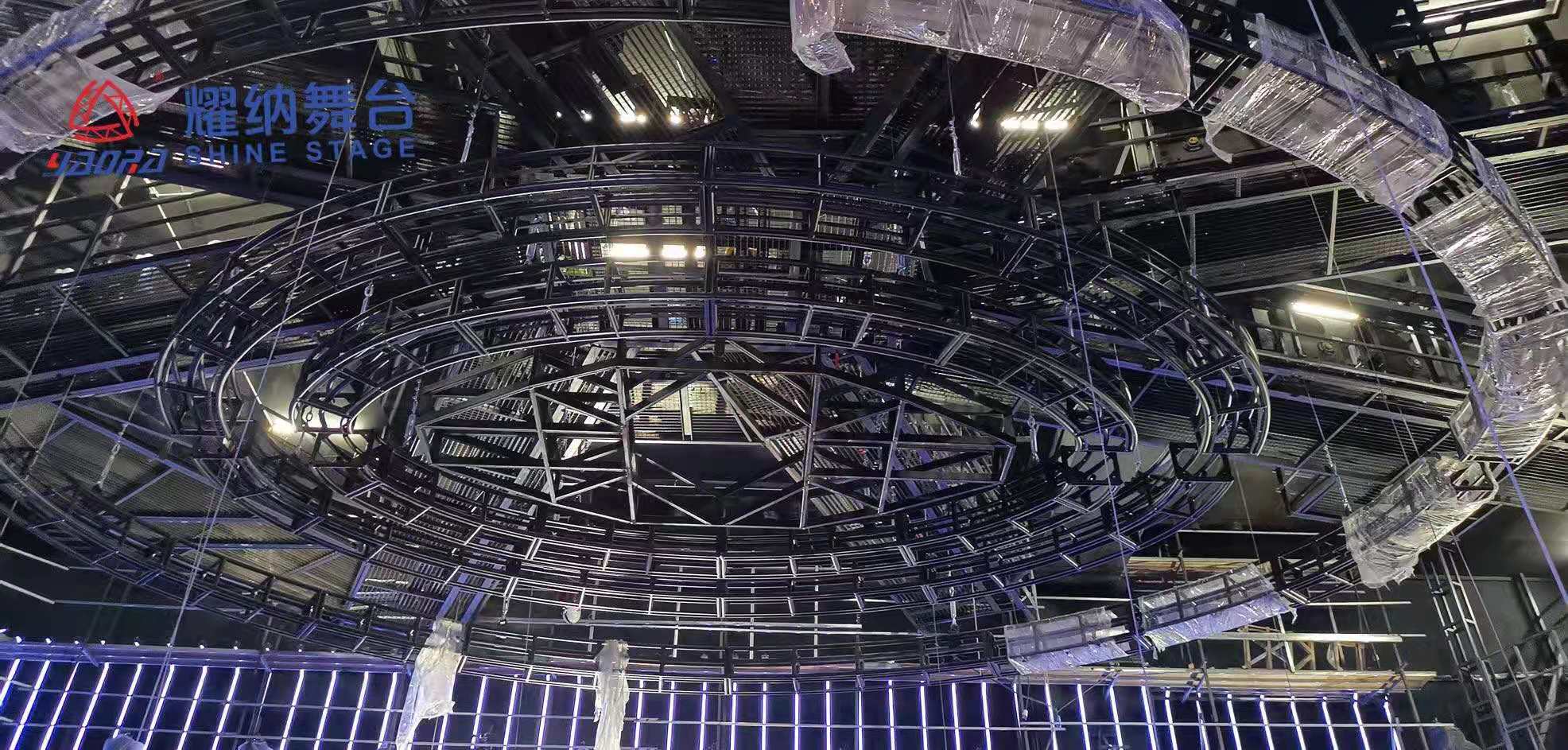

This new direction is not simply about hardware—it’s about a philosophy of design. Modular engineering brings together structural precision and creative freedom. Each element of the system, from platform frames to connection clamps, is carefully calculated, tested, and certified. Yet these components can be reassembled in countless ways, forming stages for music festivals, cultural performances, or sports events. Behind every configuration lies the same principle: a repeatable system that ensures safety and efficiency without limiting artistic imagination.

Efficiency has become the new measure of value in event production. Every minute saved in setup and teardown is directly reflected in cost reduction, logistical simplicity, and greater flexibility for organizers. Modular systems make it possible to use fewer people, lighter tools, and shorter schedules. Touring productions can move seamlessly from one city to another, rebuilding the same performance space with consistent safety and visual standards. For production teams that work across borders, the ability to reuse a stage design across multiple countries represents not only convenience but strategic financial advantage.

The global stage market has also undergone a quiet but profound standardization. Different regions once followed different structural norms, leading to delays in approvals and redesigns. Modular stage systems have bridged that gap, integrating certifications such as TUV, CE, and ANSI into their production process. This ensures that a structure approved in Germany can be safely installed in the United States or China with minimal adjustment. A global stage now speaks one technical language—safe, efficient, and universally recognized.

Safety remains the foundation of all this progress. In modular systems, safety is no longer an afterthought—it is designed into every beam and joint. High-tensile aluminum alloys replace heavy steel, offering strength without excessive weight. Non-slip surfaces, reinforced corner clamps, and mechanically locked connectors prevent accidental dislodging during performance. The modular nature itself adds a layer of protection: because every connection is standardized, there is less room for human error. Each piece has already passed its stress tests long before it reaches the site.

Sustainability has also emerged as a defining principle of modern stage engineering. Traditional stage construction was often wasteful—temporary installations that required new materials for every project. In contrast, modular systems rely on reusable components that can serve hundreds of events. This not only reduces raw material consumption but also minimizes transport weight and energy use. Reusability turns environmental responsibility into economic advantage: the same system that reduces waste also maximizes long-term returns. For an industry once dependent on disposability, modular engineering represents a cleaner, smarter, and more sustainable future.

The shift toward modularity is also a story of collaboration. It aligns the thinking of engineers, designers, and event producers under one unified vision. Instead of designing a stage from scratch for every project, professionals now operate within a shared framework—predictable in its logic but limitless in its possibilities. Digital modeling tools allow structural engineers and creative directors to visualize and calculate together, balancing aesthetics and stability. This synergy saves time, enhances safety, and ensures that the final result delivers both visual impact and engineering integrity.

The investment logic behind modular stage systems follows a clear pattern: predictable input, scalable output. Once a company owns a modular stage system, it can deploy it repeatedly across multiple projects without losing performance quality. Each event adds to the value of the system rather than depleting it. In an industry where tight deadlines and shifting budgets are constant, this repeatability translates into control—control over timelines, costs, and outcomes. In simple terms, it turns stage building from a project expense into an operational asset.

Looking ahead, the evolution of modular stage engineering is set to deepen even further. What began as a method for efficient setup is now expanding into full-process integration. Stages, grandstands, and access systems are increasingly designed as interconnected units—each part engineered to support the other. Rather than separate products, they are becoming components of a unified system that can adapt to diverse environments, from indoor theaters to outdoor arenas.

This systemic approach allows event organizers to focus on creativity rather than logistics. It reduces on-site decision-making, shortens coordination chains, and ensures consistent quality from design to dismantling. As a result, large-scale productions become not just achievable but predictable—delivered on schedule, on budget, and with measurable safety performance.

The future of the stage industry lies in precision and repeatability. Modular systems have proven that technical rigor and artistic vision are not opposites—they are partners. A performance space is no longer just a physical platform but a modular framework that connects design, efficiency, and human experience. Whether for global tours, cultural festivals, or city-scale celebrations, the modular approach transforms the stage into a living system—reliable, adaptable, and endlessly creative.

The global shift toward modular stage engineering signals a new era in the relationship between art and structure. It brings together decades of craftsmanship, the discipline of modern engineering, and the momentum of global innovation. In this transformation, companies like Shinestage stand at the crossroads of technology and performance—delivering not just equipment, but a new way of building, presenting, and experiencing the stage itself.