CASES & NEWS

Related News

Related Products

The Ultimate Buyer’s Guide: How to Choose the Right Stage Truss Manufacturer

Views:

Author: Shinestage

Publish Time: 2025-08-22

Origin:

Investing in stage truss is an important business decision that is not only about cost but is directly related to a project’s safety and reputation. When faced with a wide variety of products and manufacturers on the market, how can you make an informed choice? This ultimate buyer’s guide will provide an in-depth analysis of the key factors to consider when purchasing stage truss. From understanding load-bearing parameters and interpreting safety certifications to evaluating a manufacturer’s strength and services, Shinestage will share years of industry experience to help you avoid pitfalls, choose the right partner, and ensure every investment is worthwhile and safe.

I. Core Considerations: Product Technology and Safety Performance

In stage truss procurement, while price is important, safety performance and technical specifications are the top priorities.

1. Material is the Foundation: Beware of Inferior Aluminum

As we mentioned before, the truss material determines its performance.

Look for 6082-T6: Ask the manufacturer if they use the international standard 6082-T6 aluminum alloy. Some low-priced products may use recycled or non-standard aluminum, which cannot guarantee the same strength and corrosion resistance.

Request Material Certificates: A good manufacturer will be happy to provide material composition analysis reports and hardness test reports as strong proof of their product quality.

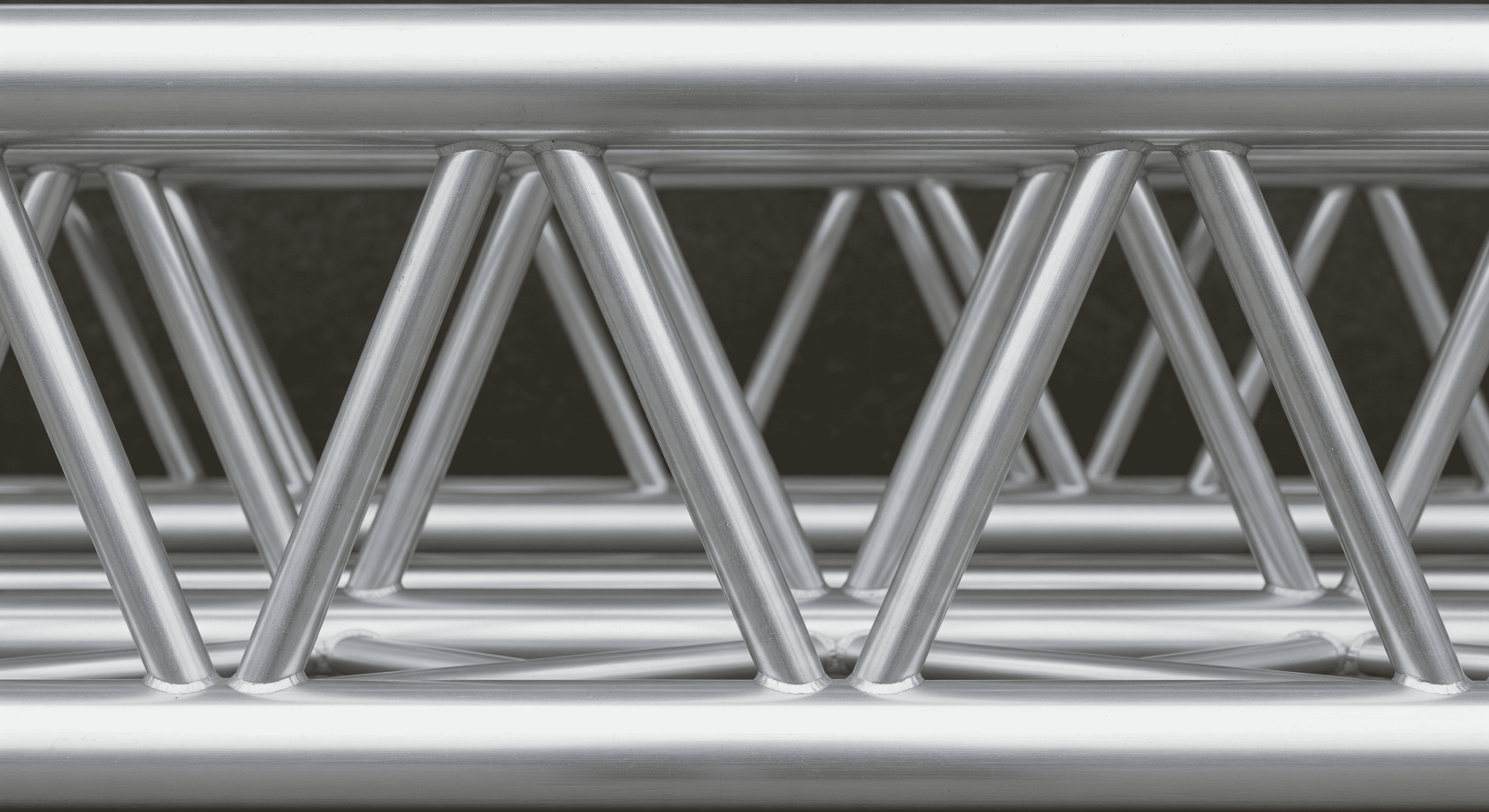

2. Welding is the Lifeline: Understand the Welding Process

Weld quality directly determines the truss’s load-bearing capacity and safety.

Inspect the Welds: Professional TIG welds are uniform, dense, and have a fish-scale pattern. If the welds are rough, irregular, or have pores, their strength and reliability may be questionable.

Ask About Welder Qualifications: Inquire whether the manufacturer’s welders are professionally certified. This reflects the professionalism of their manufacturing level.

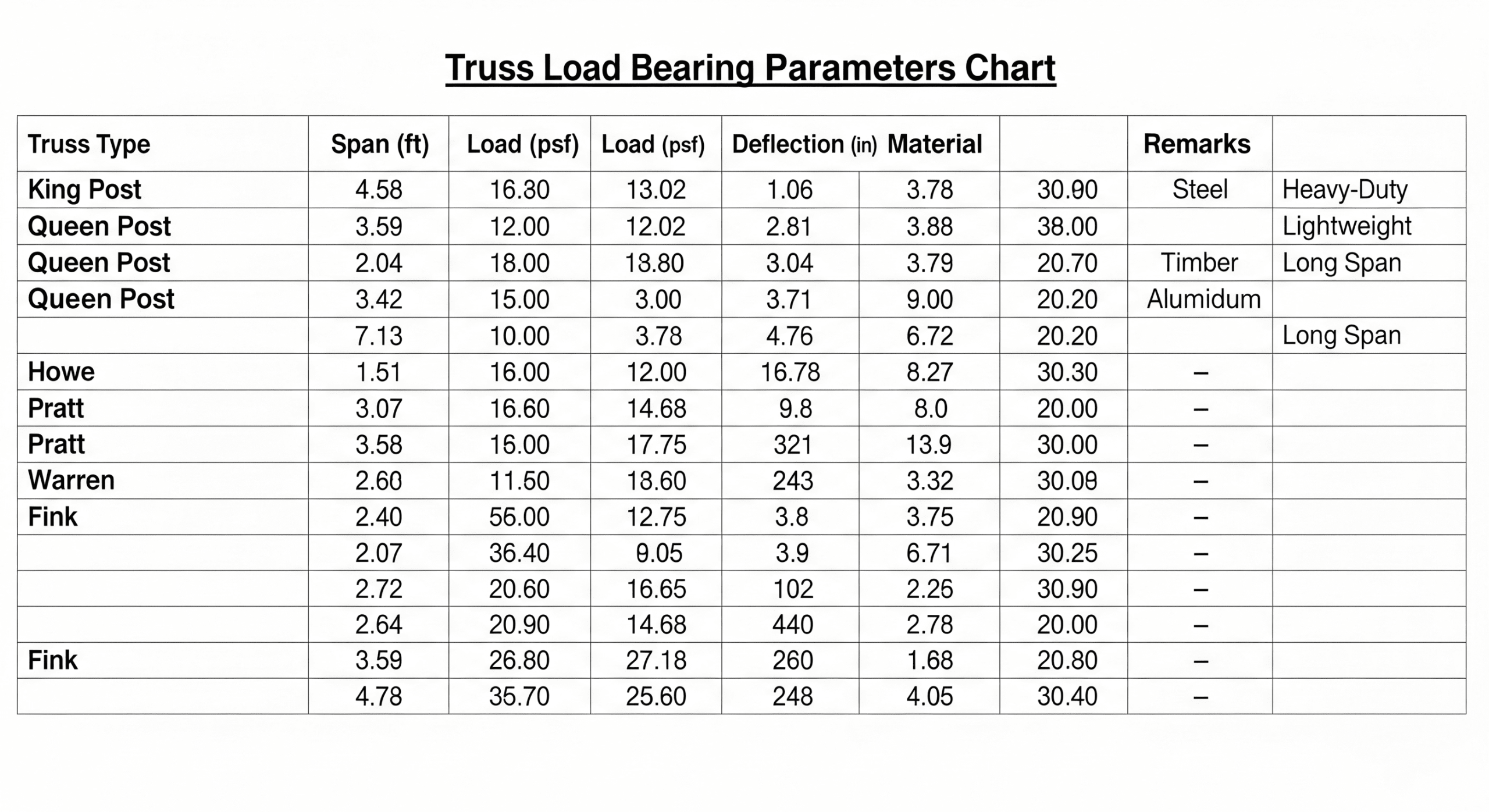

3. Read the Load Chart Correctly: Don’t Just Look at the Numbers

The load chart is the most direct indicator of truss performance. But you need to know how to interpret it correctly.

Understand the Calculation Standard: Ask what standard the load chart is based on (e.g., Eurocode 9 or AISC).

Pay Attention to the Safety Factor: Reputable manufacturers will consider a safety factor (usually 2:1 or higher) when publishing load-bearing data, meaning the actual load-bearing capacity is twice the number on the chart. Some manufacturers may publish theoretical maximum values, which can pose a huge safety risk.

Load Types: Distinguish between concentrated loads, distributed loads, and dynamic loads. Ensure the load-bearing parameters of the product you choose meet the needs of your actual application.

II. Certifications: The International Passport of Trust

Authoritative international certifications are a hard standard for measuring a manufacturer’s strength and a product’s safety.

TÜV Certification: This is one of the highest-level safety certifications in the stage equipment field. Earning TÜV certification means the product has met the most stringent standards in design, materials, manufacturing, and load-bearing capacity. This is one of the most important factors to consider when choosing a manufacturer.

CE Certification: If you plan to use the truss in the European market, CE certification is mandatory. It ensures the product meets the EU’s safety, health, and environmental requirements.

How to Verify a Certification?

Request the Certificate: Ask the manufacturer to provide the latest certification certificate.

Check the Certification Body’s Official Website: You can check the authenticity of the certificate on the official websites of certification bodies like TÜV.

III. Service and Support: Key to Long-Term Partnership

Purchasing truss is not a one-time transaction; it requires long-term service and support.

1. Professional Technical Consultation

Solution Design: A good manufacturer not only sells products but also provides professional solution design and structural calculation services based on your project needs.

On-Site Guidance: For large-scale projects, whether a manufacturer can provide professional on-site setup guidance is crucial for ensuring safety and efficiency.

2. After-Sales Service and Maintenance

Spare Parts Supply: Ask if the manufacturer provides original spare parts for future replacement of damaged components.

Maintenance Guide: A good manufacturer will provide a detailed maintenance and care manual to help you extend the life of your equipment.

IV. Shinestage: Your Trustworthy Partner

At Shinestage, we understand the complexity of purchasing decisions. We provide not only high-quality stage truss that meets both TÜV and CE certifications but also comprehensive services and support.

Quality Assurance: We strictly control every step of the production process to ensure every product has exceptional performance and unparalleled safety.

Technical Support: Our strong engineering team can provide free solution design and technical consultation for your project.

Global Service: No matter where you are, we can provide you with professional logistics, installation guidance, and after-sales support.

Choosing Shinestage means choosing a partner who is responsible for quality, safety, and their customers. We look forward to working with you to build the most solid and reliable foundation for your project.